1. Start by locating the spark plugs and their respective wires on your vehicle’s engine.

2. Disconnect each wire from its corresponding spark plug at both ends, then measure the length of the wire with a measuring tape or ruler to determine how much you need to shorten it.

3. Cut off excess wiring at both ends using heavy-duty scissors or electricians’ snips, leaving enough room for you to reattach the connectors after shortening the wires as necessary.

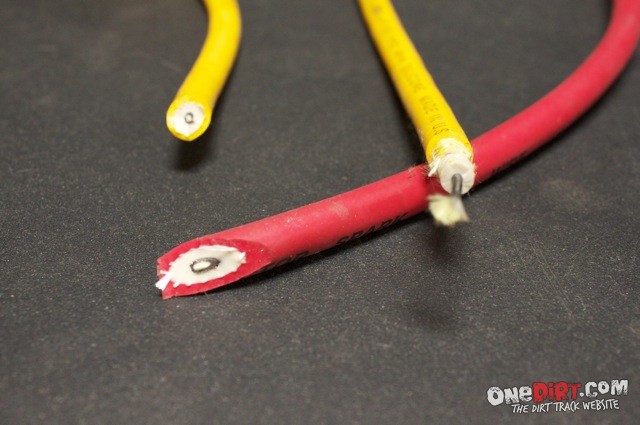

4. Use a pair of pliers to remove any insulation that was cut off along with extra wiring from one end of each connection point separate them into two halves using a flathead screwdriver and careful prying motion so that only exposed copper strands are visible in between them .

5. Insert 1/4 inch spade terminals onto opposite sides of each removed connector half and crimp them together tightly using an electrical crimping tool for better contact points when reattaching later .

- Gather the necessary tools – You will need a socket wrench, spark plug wire pliers and a pair of scissors or snips

- Remove old wires – Unscrew the spark plugs from their sockets using the socket wrench and remove any existing spark plug wires that are connected to them

- Determine new length – Measure the distance between each spark plug and its corresponding distributor cap or ignition coil with a measuring tape to determine how long you will need to make your new spark plug wires

- Cut new wires – Use either scissors or snips cut two pieces of insulated wire that are slightly longer than what you measured in step 3 so that they can easily reach both ends without being too tight when installed on the car engine components such as distributor caps and ignition coils

- 5

- Crimp ends -Using your spark-plug wire pliers, secure one end of each piece around one side of a terminal boot (either distributor cap or coil) by crimping it tightly into place; repeat this process for all four terminals boots until they are secured onto all four sides respectively

- 6 Install Wires– Plug in each newly shortened wire into its respective terminal boot (distributor cap or coil)

- Make sure that none of them overlap with one another before tightening down the connections with your socket wrench

How to – Shorten / Terminat Spark plug wires

How to Clean Spark Plug Wire Boot

To clean spark plug wire boots, you should first disconnect them from the spark plugs and use a soft brush to remove any dirt or debris. Once the exterior is clean, you can use an aerosol electrical contact cleaner to spray inside each boot to remove any residue or corrosion. After cleaning the boots thoroughly, be sure to wipe away excess moisture before re-attaching them to your spark plugs.

Credit: www.dragzine.com

Can I Shorten a Spark Plug Wire?

Yes, you can shorten a spark plug wire. Spark plug wires are designed to transfer the electrical charge generated by your car’s ignition coil to the spark plugs in each cylinder of your engine. Over time, these wires can become worn and stretched due to normal wear and tear or exposure to heat and moisture, which is why it’s important that you replace them when necessary.

However, if you’re confident with using tools such as pliers and scissors or wire strippers, then shortening a spark plug wire yourself is an easy task that will save you money compared to buying new ones. Before starting this project, make sure that you have the correct size replacement terminal ends (usually brass) for your vehicle’s model year so they fit properly on both the distributor cap side and the spark plug side once reattached after cutting off some length from the center of the wire. Once everything is ready for installation, use diagonal cutters or strong scissors to snip away any excess material from either end of the cable before crimping on new terminals with vice-grips or pliers; making sure not to damage any insulation along its surface which could cause shorts down road .

Finally test out all connections before driving off!

What Happens If Spark Plug Wires are Too Long?

If spark plug wires are too long, they can cause misfiring or weak ignition. This occurs because the excessive length of the wire causes it to pick up more resistance and create a greater voltage drop. As this happens, less power is transmitted to ignite the fuel-air mixture in your engine’s combustion chamber.

This weaker spark can make it difficult for your engine to run properly, resulting in reduced performance and increased emissions. Additionally, if the wires are too long they may not fit securely onto their corresponding terminals on either side of the plug which could lead to arcing and eventual failure of the wiring system itself. It is therefore important that when replacing or installing new spark plugs that you get measurements that correspond with your vehicle’s manufacturer specifications so as not to place unnecessary strain on its components.

Does the Length Matter on Spark Plug Wires?

When it comes to spark plug wires, the length of the wire can have a significant impact on engine performance. The length of the spark plug wire affects how much voltage is transmitted from one end to the other and this, in turn, affects how well your engine performs. Short wires can limit peak power output while long wires can cause cross-fire between cylinders or lead to misfires due to an inadequate spark.

Therefore, choosing the right length for your vehicle’s spark plug wires is essential if you want optimal performance out of your engine. Longer than necessary cables will take away some of that energy before it reaches its destination; shorter than necessary cables may not deliver enough voltage or current for a proper ignition burn at high RPMs. The correct length should be determined by measuring from terminal to terminal and then subtracting 1/4 inch for each connection point along the way—including any terminals inside distributor caps or coil packs as applicable.

In addition, using premium quality wiring such as those made with Kevlar insulation helps ensure consistent performance over time without any voltage loss due to aging materials or wear and tear on connectors. With all these factors taken into consideration, there’s no doubt that having properly sized spark plug wires plays an important role in maximizing your car’s potential power output!

How Do You Cut Back Spark Plug Wires?

Cutting back spark plug wires is a relatively simple task, but it’s important to do the job right. Start by selecting the correct size and length of wire for your application. After you’ve chosen the right wire, use a pair of side-cutting pliers or diagonal cutters to snip off any excess material that extends beyond its intended length.

Once the excess has been trimmed away, use a pocket knife or razor blade to carefully strip away about 1/4 inch of insulation from each end of the wire. This will give you enough room to attach connectors on either end without creating an exposed short circuit between them. Finally, twist together strands of metal at both ends and crimp on desired style connector with specialized tool designed for this purpose – such as spark plug terminal crimping tool – then slide rubber boot over connected sections and ensure all connections are secure before reinstalling into engine compartment.

Conclusion

In conclusion, shortening spark plug wires is a relatively easy DIY task that can make a big difference in your vehicle’s performance. This job requires minimal tools and supplies and with patience, you should be able to complete the job without any trouble. With new spark plug wires installed correctly, your engine will run smoother and more efficiently than ever before.