Straight cut gears work by utilizing teeth that are cut straight on the gear faces to transfer power from one gear to another. As the teeth mesh together, the power is transmitted seamlessly through the gear train.

These gears are commonly used in racing applications because they can handle higher torque loads and are more efficient than helical or bevel gears. Straight cut gears are a popular choice among racers because of their performance-enhancing qualities.

Unlike helical or bevel gears, straight cut gears feature teeth that are cut straight on the gear faces. These gears can handle higher torque loads and are more efficient, making them ideal for high-performance racing applications. When the teeth mesh together, the power is transmitted seamlessly through the gear train, allowing for greater acceleration and speed.

While straight cut gears are louder than helical or bevel gears, their performance benefits make them a preferred option for racers looking to gain an edge on the competition.

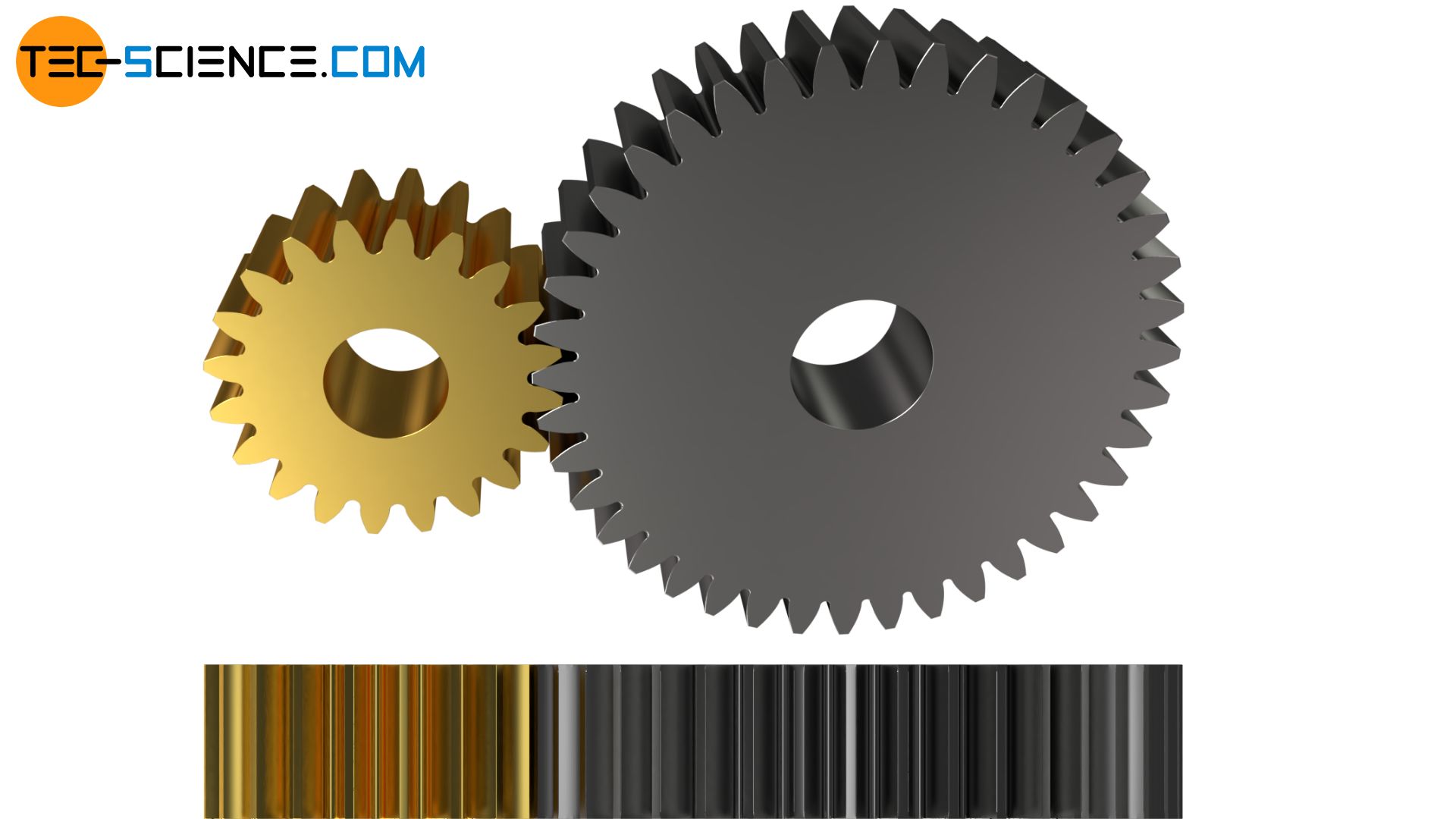

Credit: www.tec-science.com

The Basics Of Gear Design

Gear design is a critical aspect of mechanical engineering. Gears are categorized by their shape, size, and purpose, with straight cut gears being one of the most common designs. The straight cut gears transmit motion between two rotating shafts, with teeth aligned parallel to the axis of rotation.

Helical, bevel, and worm gears are other variations of gear types. Gear design also takes into account factors such as transmission efficiency, noise reduction, and load-carrying capacity. A well-designed gear system can significantly improve machine performance, longevity, and reliability. It is essential to understand gear design basics to choose the right gear type for an application.

How Straight Cut Gears Are Different

Straight cut gears are different from helical gears because they have straight teeth that engage simultaneously. Helical gears have angled teeth that engage gradually. The advantages of straight cut gears are that they are more efficient, provide better torque at high rpms, and are often used in racing cars.

The disadvantages include noise, vibration, and the fact that they cannot handle as much load or torque as helical gears. Straight cut gears are also more expensive to produce. Despite their drawbacks, straight cut gears remain popular among performance enthusiasts because of their unique properties.

If you’re considering using straight cut gears, it’s important to weigh the pros and cons carefully to determine whether they’re the right choice for your application.

HELICAL VS. STRAIGHT CUT GEARS | Donut Media

Principles Of Straight Cut Gear

Straight cut gears are designed to transmit power smoothly and efficiently, with gear teeth arranged in parallel. The gear ratio determines the speed and torque of the drive, with higher ratios delivering more torque but lower speeds. Tooth profile plays an essential role in determining how gears interact with each other and their strength, with tapered teeth providing more significant contact area, and straight ones reducing friction.

Load distribution affects the durability and performance of the gear, with heavier loads placed on wider and thicker teeth. A high-quality straight cut gear system ensures a smooth power transfer and a long-lasting service life, meeting the demands of high-performance applications such as race cars, heavy machinery, and industrial equipment.

Real World Applications Of Straight Cut Gears

Straight cut gears have a variety of uses in different industries. Performance cars and racing vehicles utilize them to enhance their speed and acceleration. Heavy-duty machinery depend on them to handle increased loads and ensure smooth operation. Industries also apply them for everyday industrial purposes such as in fans, compressors, and water pumps.

In domestic settings, straight cut gears are prevalent in household appliances like washing machines and mixers. They are advantageous in numerous ways including their ability to transmit power efficiently and their less complex design. With increased demand for machines that perform at high levels, it’s no wonder straight cut gears have gained popularity across a broad range of applications.

Frequently Asked Questions For How Do Straight Cut Gears Work

How Do Straight Cut Gears Work?

Straight cut gears transfer power directly from one gear to another, without using a compound gear.

What Are The Benefits Of Straight Cut Gears?

Straight cut gears can handle more power, reduce rotational mass, and provide faster gear changes.

Why Are Straight Cut Gears Louder Than Helical Gears?

Straight cut gears have square-cut teeth that mesh directly, causing a whining sound. Helical gears have angled teeth for quieter operation.

Conclusion

Ultimately, the straight cut gears are a crucial component of any high-performance engine. Its efficient functionality allows for engine gearboxes to handle high horsepower more effectively than their synchromesh counterparts. The straight cut gears’ mechanical advantage, smoothness of operation, and durability make them an ideal choice for the racing and performance enthusiasts.

However, they generate an auditory buzz that may be unbearable for the average driver. The straight cut gear system has carved a niche for itself in the auto racing industry, and it delivers unrivaled performance and reliability while maintaining a significant mechanical advantage.

As a conclusion, in the pursuit of maximizing the horsepower output from a vehicle, investing in straight cut gears is an excellent starting point.